The project “FiBrane: A UPW Solution for Offshore Green H2 Production” aims to further develop a new membrane technology that can effectively purify seawater into ultrapure water, which is used in electrolysis processes.

Water for Power-to-X (PtX) must be ultrapure. Ultrapure water serves as the primary raw material for green hydrogen production and helps ensure the optimal performance of the electrolyser. The project addresses the challenge that the PtX value chain requires water, as abundant amounts of water are a prerequisite.

The project, located in Aalborg, is a research and development project, where the membrane technology is to be raised from Technology Readiness Level (TRL) level 4 to TRL level 6 during the project period. The project has achieved TRL level 4 with support from Horizon 2020, Spin-outs Denmark and Innovation Fund Denmark and is now seeking support to bring the membrane technology from laboratory scale to pilot plant scale.

- Beneficiaries

Coordinator: Aalborg Universitet

- Project Locations

Denmark

- EU funding

€900 000

- Funding source

Just Transition Fund in Denmark

Other STEP stories

- Highlighted

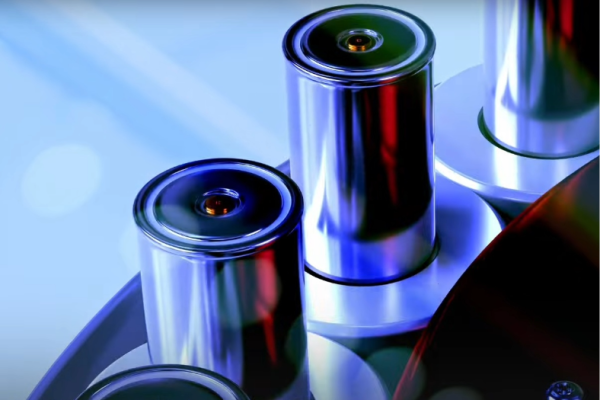

The project focuses on building a new production line for the next-generation cylindrical battery known as the 46 series, designed specifically for powering electric vehicles (EVs) and is expected to start operating in the third quarter of 2028.

- Highlighted

The AGATHE project involves expanding Verkor's battery factory in Dunkirk, France, doubling its production capacity from 8 GWh to 16 GWh. This expansion incorporates cutting-edge technologies, including automation and artificial intelligence, to make manufacturing more efficient and sustainable.

FiBrane is a groundbreaking method for efficiently transforming seawater into ultrapure water (UPW) needed for offshore green hydrogen production.