The AGATHE project involves expanding Verkor's battery factory in Dunkirk, France, doubling its production capacity from 8 GWh to 16 GWh. This expansion incorporates cutting-edge technologies, including automation and artificial intelligence to make manufacturing more efficient and sustainable. A notable feature is the introduction of a pre-recycling facility on-site, which can reuse over 95% of production leftovers, significantly decreasing waste and energy use. By adopting these advanced methods, the project not only improves product quality and reduces emissions but also promises a reduction in greenhouse gas emissions equivalent to over 12 million tonnes of CO2 in ten years.

Beyond just increasing capacity, the AGATHE project promotes independence in the industry's material supply chain, supports environmental sustainability, and creates skilled jobs. Ultimately, it serves as a model for future factories, showcasing how they can be built efficiently and replicate its success elsewhere.

This initiative strengthens Europe's position in the global battery market and plays a part in the transition towards clean energy.

- Beneficiaries

Coordinator: Verkor

Participants: Giga Verkor Immo - Rekovr

- Project Locations

France

- EU funding

€76.3 million

- Funding source

Other STEP stories

- Highlighted

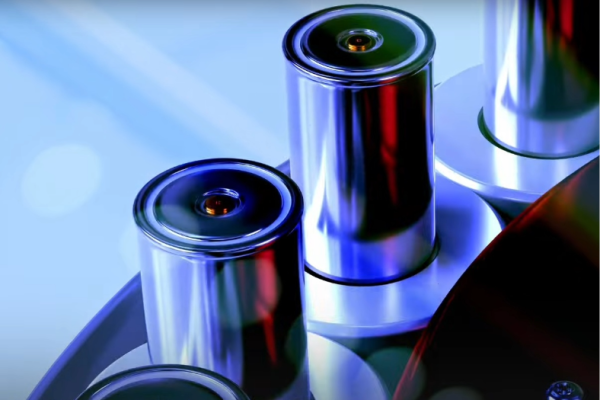

The project focuses on building a new production line for the next-generation cylindrical battery known as the 46 series, designed specifically for powering electric vehicles (EVs) and is expected to start operating in the third quarter of 2028.

- Highlighted

The AGATHE project involves expanding Verkor's battery factory in Dunkirk, France, doubling its production capacity from 8 GWh to 16 GWh. This expansion incorporates cutting-edge technologies, including automation and artificial intelligence, to make manufacturing more efficient and sustainable.

FiBrane is a groundbreaking method for efficiently transforming seawater into ultrapure water (UPW) needed for offshore green hydrogen production.