With €17.3 million from the Innovation Fund, WINDPL will build a large-scale factory in Poland to produce steel towers for the world’s largest offshore wind turbines. The facility will integrate robot-assisted manufacturing, automated welding, and recycling processes to reduce waste and defects, setting a new industry standard. Producing 100 towers per year (14 MW), the project will power 18,000 homes annually, help avoid 2.5 million tonnes of CO₂ in its first ten years of operation and create 450+ direct jobs, strengthening Europe's wind energy supply chain. The Innovation Fund is 100% funded by the EU Emissions Trading System.

- Beneficiaries

Coordinators: Windar Ren

Participants: Windar Polska sp. z o.o.

- Project Locations

Poland

- EU funding

€17.3 million

- Funding source

Other STEP stories

- Highlighted

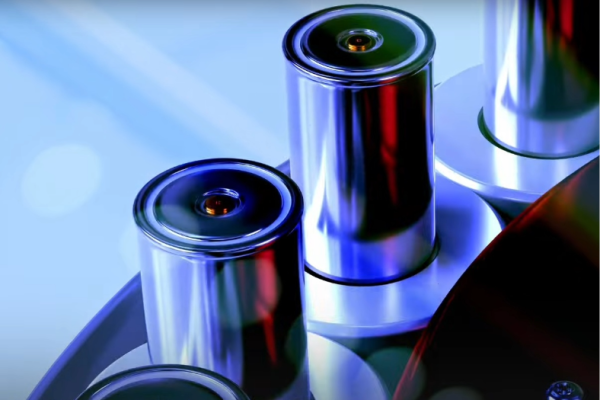

The project focuses on building a new production line for the next-generation cylindrical battery known as the 46 series, designed specifically for powering electric vehicles (EVs) and is expected to start operating in the third quarter of 2028.

- Highlighted

The AGATHE project involves expanding Verkor's battery factory in Dunkirk, France, doubling its production capacity from 8 GWh to 16 GWh. This expansion incorporates cutting-edge technologies, including automation and artificial intelligence, to make manufacturing more efficient and sustainable.

FiBrane is a groundbreaking method for efficiently transforming seawater into ultrapure water (UPW) needed for offshore green hydrogen production.